1. Monitoring Screen

-

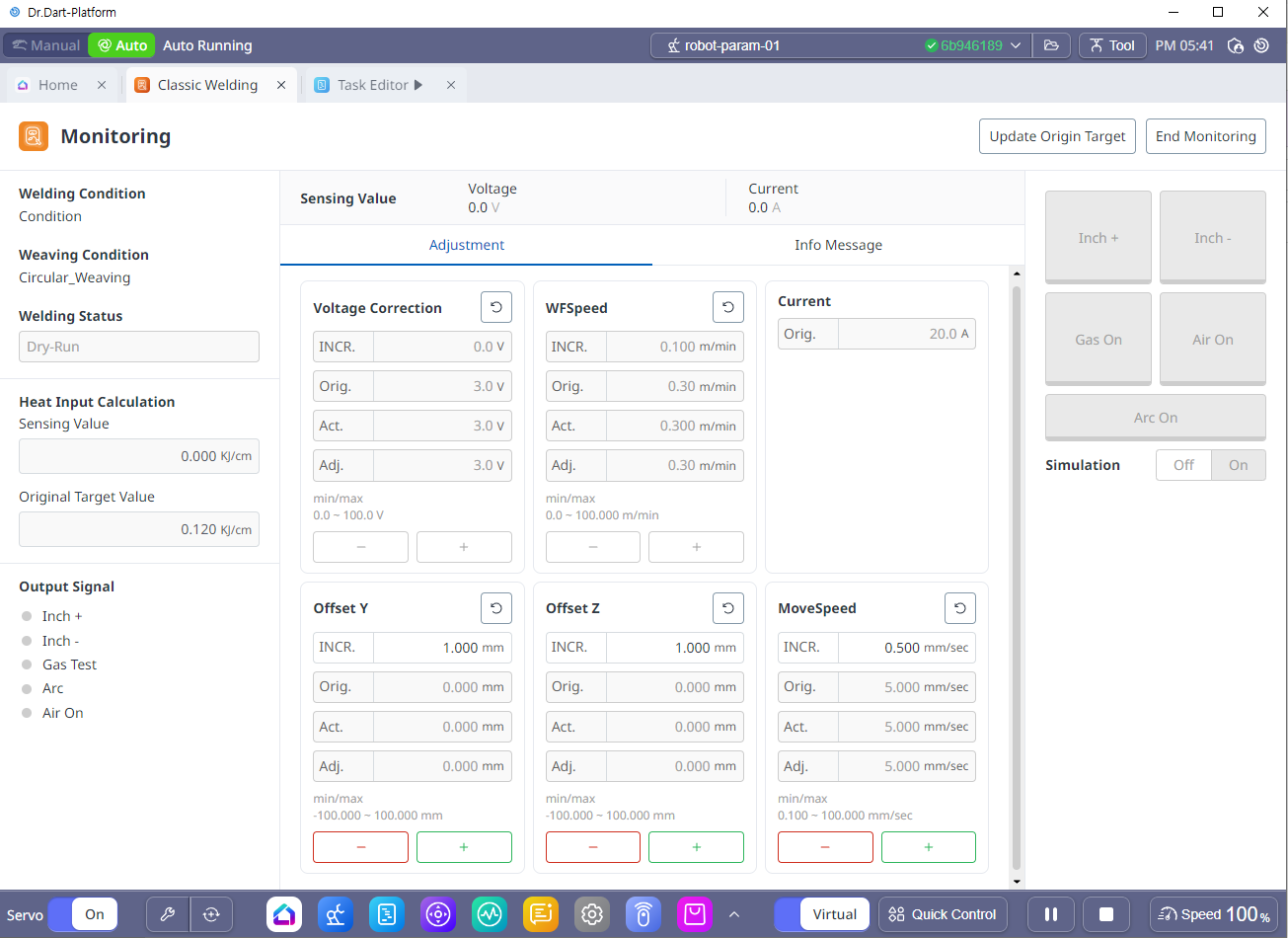

When a Task set to analog is running in the Task Editor, the analog monitoring screen appears as shown below.

|

No |

Category |

Desc |

|---|---|---|

|

1 |

Welding Condition |

Display the name of the welding condition being used in the currently running task. |

|

2 |

Weaving Condition |

Display the name of the weaving condition being used by the currently running task. |

|

3 |

Welding Status |

Display the current welding progress status of a task that includes welding. ("Welding in progress", "Error occurred", "Dry run", "Not welding in progress", etc.) |

|

4 |

Sensing Value |

Show the voltage and current values detected by the welding machine. |

|

5 |

Voltage Correction |

You can adjust the voltage value by the set INCR value using the + and - buttons below. |

|

6 |

WFSpeed |

You can adjust the transmission speed value by the set INCR value using the + and - buttons below. |

|

7 |

Current |

Show the current value set for the selected welding conditions. |

|

8 |

Offset Y |

You can adjust the offset Y value of the selected weaving by the set INCR value using the + and - buttons below. |

|

9 |

Offset Z |

You can adjust the offset Z value of the selected weaving by the set INCR value using the + and - buttons below. |

|

10 |

MoveSpeed |

When welding, you can adjust the movement speed by the set INCR value using the + and - buttons below. |

|

11 |

Update Origin Target |

Save the adjusted values as the default values for the selected welding conditions. |

|

12 |

Simulation |

You can play the welding task without running the welding machine. If you turn the simulation mode “on” and then play the task, you can check the path and weaving motion first, and adjust interference or offsets on the welding path to prevent unexpected errors during actual welding. |