Safety-rated Stop Function

Safety Function | Safety Function Trigger Condition Triggering Event | Intended Action Intended result | PFHd | PL, SIL | |

|---|---|---|---|---|---|

| 1 | Emergency Stop | If the Emergency Stop switch connected to the TBSFT EM terminal is pressed If the Emergency Stop switch of the teach pendant is pressed | Emergency Stop is engaged according to the configured Safety Stop Mode.

| 2.87E-8 /h | PL e Cat. 4 SIL 3 |

| 2 | Protective Stop | In case the protective equipment connected to the PR terminal of TBSFT is activated, | Emergency Stop is engaged according to the configured Safety Stop Mode.

| 4,63E-7 /h | PL d Cat. 3 SIL 2 |

How to resume work after a protective stop

If the tool center point (TCP) of the robot is within the Collaborative Zone and the Nudge function is enabled, the user can apply force to the robot directly (Nudge) to resume work. For more information, refer to Setting the Collaborative Zone and Nudge.

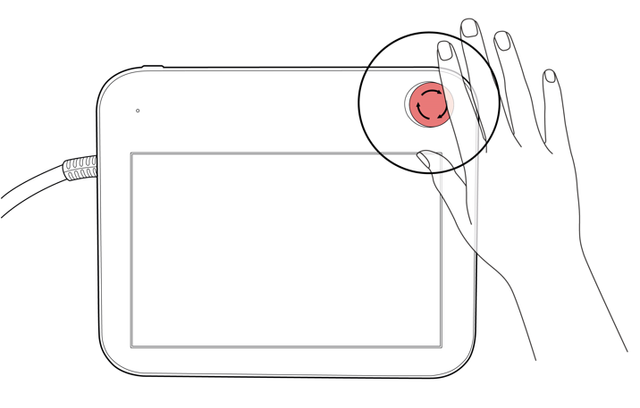

Emergency Stop

The Emergency Stop button is available to stop the system in case of an emergency. In emergency situations, press the Emergency Stop button in the top right corner of the teach pendant to immediately stop the system.

Note

Emergency stops should be used as a complementary protective measure, not as a safeguard.

The safety stop mode for the emergency stop is set to Safe Stop 1 (SS1) by default.

Additional Emergency Stop buttons can be installed if deemed necessary as a result of evaluating the risk to the robot application.

The Emergency Stop button must comply with IEC 60947-5-5.

If an emergency stop triggered through the port set in Safety I/O, the button capable of accessing the screen for Safety Input setting at the bottom of the emergency stop popup window is enabled.

Protective Stop

The robot also features Protective Stop function which can stop the robot using pressure sensitive protective equipment, such as safety matts, or electro-sensitive protective equipment, such as light curtain laser scanners.

For more information about connecting protective devices, refer to Setting the Terminal Block for Contact Input (TBSFT) and Configuring Configurable Digital I/O (TBCI1 - 4,TBCO1 - 4).