Setting up and using extended protocols

Expanded Protocol - PROFINET IO Device(pnio device) Setup

The robot controllers of Doosan Robotics support the PROFITNET IO Device (Slave) function, which allows data modification after reading the Parameters of the robot from an external device (PROFINET IO Controller/Master). (E.g., Robot parameter Monitoring, General Purpose Register(bit, Int, Float) – Using General Purpose Register (GPR))

Note) for more information about PROFINET, please visit http://www.profibus.com

Expanded Protocol - EtherNet/IP Adapter(EIP adapter) Setup

The robot controllers of Doosan Robotics support the EtherNet/IP Adapter (Slave) function, which allows data modification after reading the Parameters of the robot from an external device (EtherNet/IP Scanner / Master). (E.g., Robot parameter Monitoring, General Purpose Register(bit, Int, Float) – Using General Purpose Register (GPR))

Note 1) For more information about EtherNet/IP, refer to www.odva.org.

Note 2) the initial default IP is 192.168.137.50. After that, you can change the controller IP depending on the use of the PLC control application.

Using Expanded Protocol

The PROFINET IO Device (PNIO device) and EtherNet/IP Adapter (EIP adapter) functions start together at controller startup, and are in connection standby state with the Master device. Therefore, in order to use the function, it is necessary to connect and set up the Master. Each Master device has different characteristics, so it is necessary to check them.

Note

The following are descriptions of the implementation characteristics of general functions for Industrial Ethernet.

The Industrial Ethernet function of Doosan Robotics controllers does not use a separate ASIC, but implements its function based on TCP/IP, so it does not support real-time performance.

Data output to external devices has identical markings (PNIO, EIP), but data input to the robot only has identical structures and does not link. Therefore, data output from the PNIO controller does not synchronize with output data from the EIP scanner.

For the I/O table of PNIO and EIP, please refer to a separate document (or attachment).

EtherNet/IP Full GPR map

EtherNet/IP Full GPR map is available that supports different types of I/O in the robot.

Bit I/O GPR 24ea

Integer I/O GPR 50ea

Float I/O GPR 50ea

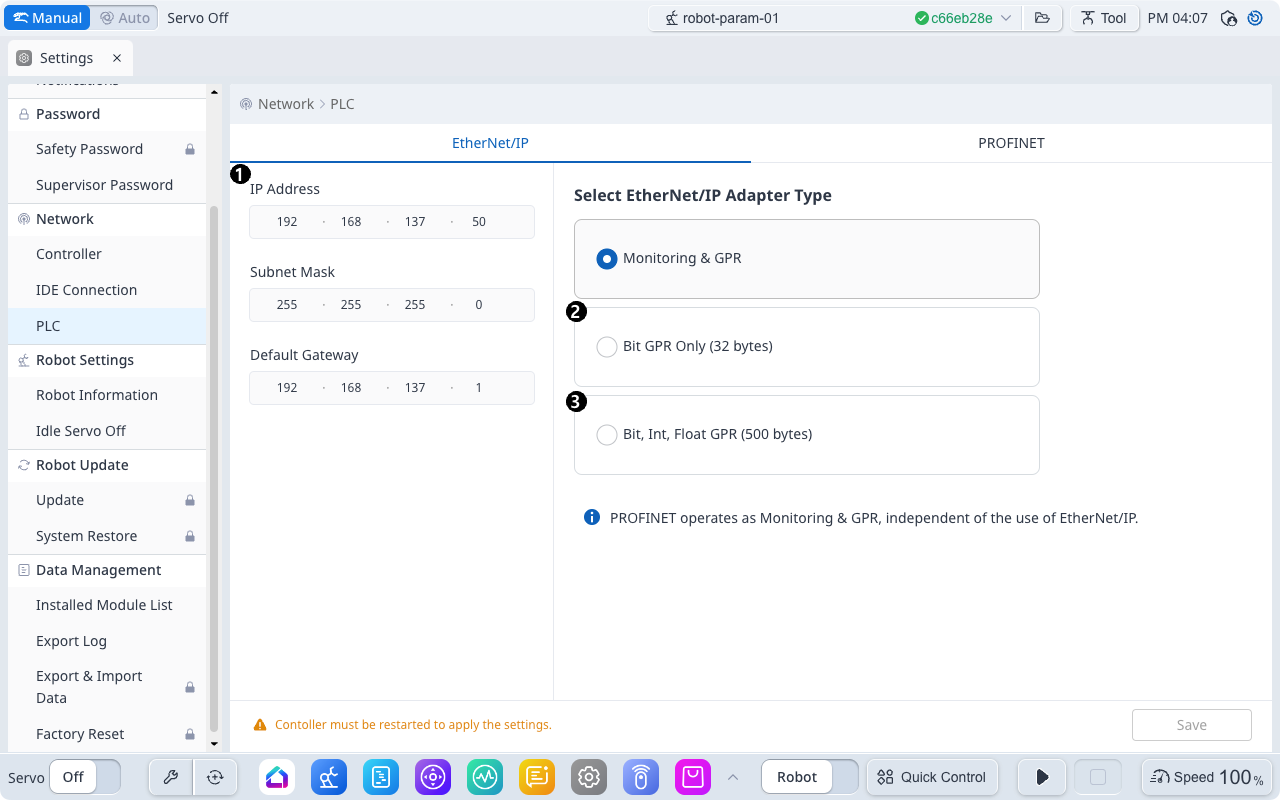

From the left menu of the Settings module, select PLC to go to the below screen. (Please refer to Configure in the Network section)

In the image below, item 3 is Full GPR map, and the setting is saved only after saving and rebooting.

ProfiNet Slot

For network optimization, only interested slots can use the ability to perform Transaction.

Slot#1: Robot State (T2O)

Slot#2: Robot Error Code (T2O)

Slot#3: Joint (T2O)

Slot#4: Task (T2O)

Slot#5: Bit GPR (T2O)

Slot#6: Int GPR (T2O)

Slot#7: Float GPR (T2O)

Slot#8: I/O Control (O2T)

Slot#9: Bit GPR (O2T)

Slot#10: Int GPR (O2T)

Slot#11: Float GPR (O2T)

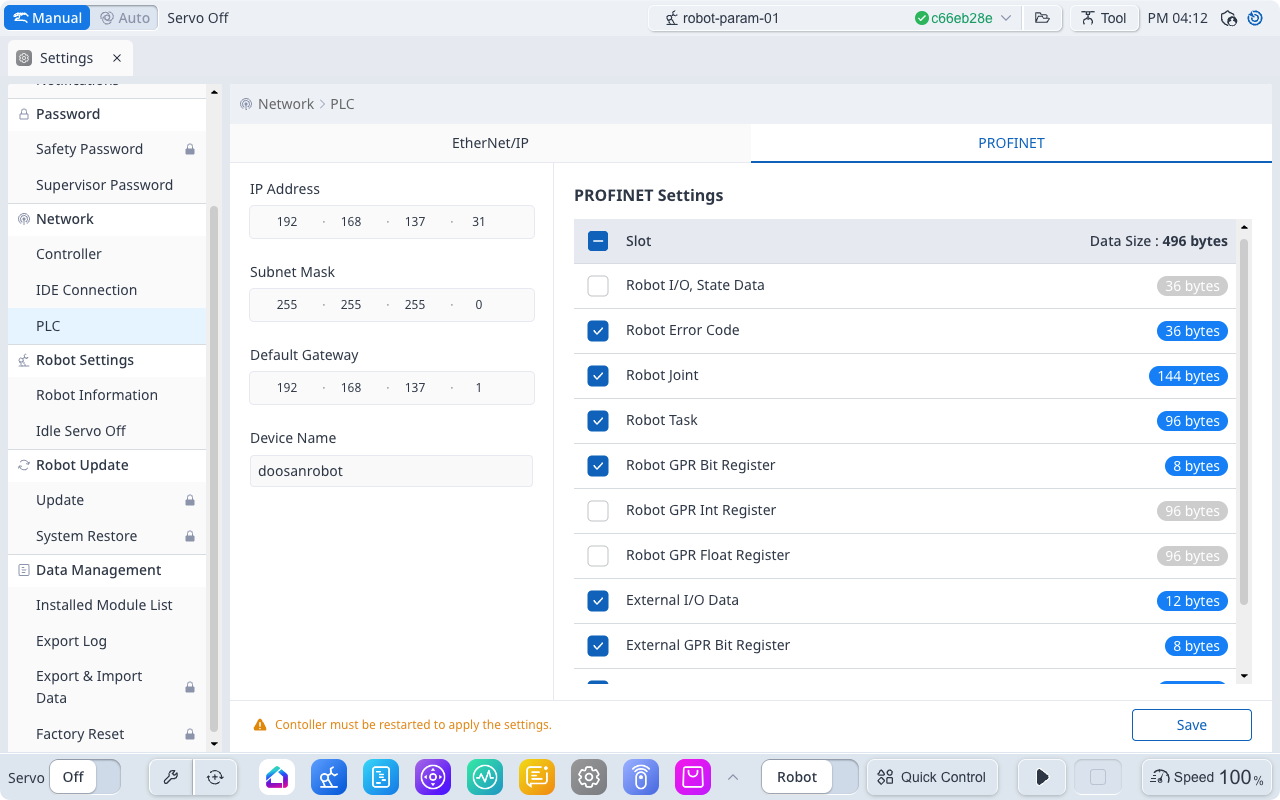

From the left menu of the Settings module, select PLC and select the ProfiNet tab to see the screen below. (Please refer to Configure in the Network section)

You can use the check box at the center to select only the slots that the user is interested in, and the settings are saved only after saving and rebooting.

Robot Error Code Information

In an environment without TP (HMI), user can check the error code information of the robot through PLC. (Please refer to Configure in the Network section)

EtherNet/IP

Note

EtherNet/IP reflects up to two error codes due to the transaction limit (500 bytes).

Byte Offset | Description |

|---|---|

36 | Major & Minor (Error Code#1)

|

40 | Year & Month & Day & Hour (Error Code#1)

|

44 | Minute & Second & Milli-second (Error Code#1)

|

48 | Major & Minor (Error Code#2)

|

52 | Year & Month & Day & Hour (Error Code#2)

|

56 | Minute & Second & Milli-second (Error Code#2)

|

ProfiNet: Slot#2

Byte Offset | Description |

|---|---|

0 | Major & Minor (Error Code#1)

|

4 | Year & Month & Day & Hour (Error Code#1)

|

8 | Minute & Second & Milli-second (Error Code#1)

|

12 | Major & Minor (Error Code#2)

|

16 | Year & Month & Day & Hour (Error Code#2)

|

20 | Minute & Second & Milli-second (Error Code#2)

|

24 | Major & Minor (Error Code#3)

|

28 | Year & Month & Day & Hour (Error Code#3)

|

32 | Minute & Second & Milli-second (Error Code#3)

|