(2.11.2-en_US) app_weld_set_weld_cond_analog(flag_dry_run=0, v_target=0, f_target=0, vel_target=0, vel_min=0, vel_max=0, weld_proc_param=[0.2,0.2,0.5,0.5,0.5,0.2,0.2,0.5,0.5])

Features

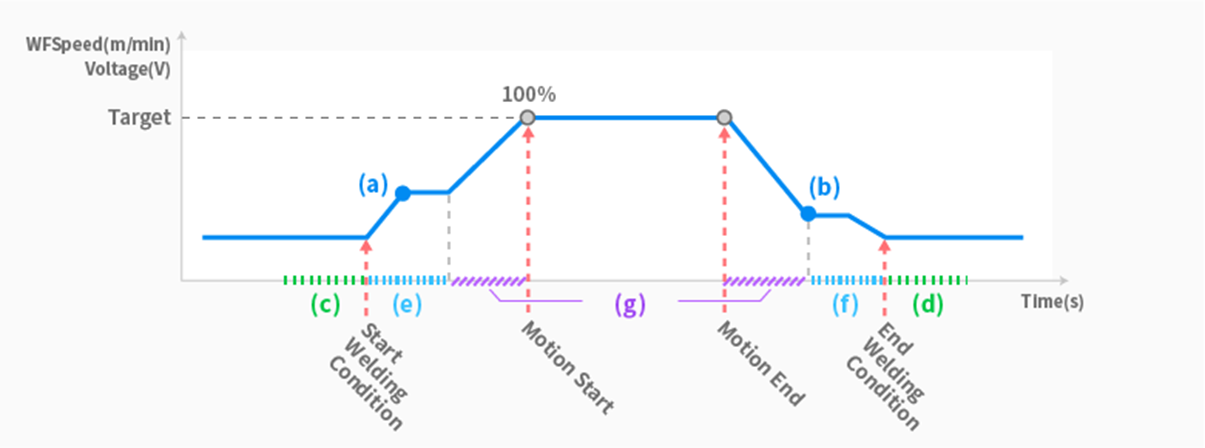

This sets the analog welding condition. It is only valid within the welding section defined with the Enable Welding (app_weld_enable_analog()) and Disable Welding (app_weld_disable_analog()) commands, and any operations starting at a point outside the welding section will generate an error. The Welding Parameter (weld_proc_param) of the welding condition displays detailed conditions, including gas during start/end welding and condition maintenance time. Refer to the figure below for the values to enter. Only one welding condition is allowed in a single welding section. This welding condition can be adjusted during welding with the app_weld_adj_welding_cond_analog() command while the voltage/feeding speed/speed (and weaving offset) can be also adjusted from the Welding Condition Adjustment popup of the teaching pendant. However, from the teaching pendant, welding condition adjustments are only available if the welding condition adjustment status is set to RESET using a command (the welding condition setting is designated with app_weld_set_weld_cond_analog()).

Note

The welding current varies according to the wire feeding speed, basic material, material/type/stick-out of the welding wire, and welding voltage, and this must be monitored with the welding machine or a separate current sensor.

(a)Rsf/Rsv (b)Rff/Rfv (c)Tss (d)Tsf (e)Tas (f)Taf (g)Twc

Parameter

| Parameter Name | Data Type | Default Value | Description |

|---|---|---|---|

flag_dry_run | int | 0 | Dry-Run Mode Actual Welding (0) Dry-Run (1): Motion/Weaving/Offset only |

v_target | float | 0 | Target Voltage (V) |

f_target | float | 0 | Target Feeding Speed (m/min) |

vel_target | float | 0 | Target Speed (mm/sec)

|

vel_min | float | 0 | Minimum Target Speed Correction (mm/sec)

|

vel_max | float | 0 | Maximum Target Speed Correction (mm/sec)

|

weld_proc_param | list(float[9]) | 0.2 | Rsf (Feeding Speed Start Condition/Target Condition Ratio) (0< Rsf <= 1) |

0.2 | Rsv (Voltage Start Condition/Target Condition Ratio) (0< Rsv <= 1) | ||

0.5 | Tss (Protective Gas Discharge Time Before Welding, sec) (0<= Tss) | ||

0.5 | Tas (Start Welding Condition Maintenance Time, sec) (0<= Twc) | ||

0.5 | Twc (Change Welding Condition Time, sec) (0<= Twc) | ||

0.2 | Rff (Feeding Speed End Condition/Target Condition Ratio) (0< Rff <= 1) | ||

0.2 | Rfv (Voltage End Condition/Target Condition Ratio) (0< Rfv <= 1) | ||

0.5 | Taf (End Welding Condition Maintenance Time, sec) (0<= Taf) | ||

0.5 | Tsf (Protective Gas Discharge Time After Welding, sec) (0<= Tsf) |

Return

| Value | Description |

|---|---|

0 | Setting Success |

Negative value | Setting Failure |

Exception

| Exception | Description |

|---|---|

DR_Error (DR_ERROR_TYPE) | Parameter data error |

DR_Error (DR_ERROR_VALUE) | Invalid parameter value |

DR_Error (DR_ERROR_RUNTIME) | C Extension module error |

DR_Error (DR_ERROR_STOP) | Program terminated forcibly |

Example

app_weld_enable_analog(ch_v_out=[1,1], spec_v_out=[0,0,300,10], ch_f_out =[2,1],

spec_f_out =[0,0,40,10], ch_v_in =[1,1], spec_v_in =[0,0,300,10], ch_c_in =[2,1],

spec_c_in=[0,0,40,10], ch_arc_on=1, ch_gas_on=2, ch_inching_fwd=3, ch_inching_bwd=4, ch_blow_out=5)

app_weld_set_weld_cond_analog(flag_dry_run=1, v_target=24, f_target=20, vel_target=60, vel_min=10,

vel_max=100, weld_proc_param=[0.2,0.2,0.5,0.5,0.5,0.2,0.2,0.5,0.5])

# Target Voltage/Feeding Speed = 24 V, 20 m/min, Welding Speed=60 mm/sec (=1 cm/min), Actual Welding, Use Default Welding Parameter

app_weld_disable_analog()

Related commands

- (V2.11.0.1_temp-en_US) app_weld_enable_analog(ch_v_out=[1,0], spec_v_out=[0,0,0,0], ch_f_out=[2,0], spec_f_out=[0,0,0,0], ch_v_in=[1,0], spec_v_in=[0,0,0,0], ch_c_in=[2,0], spec_c_in=[0,0,0,0],ch_arc_on=1,ch_gas_on=2,ch_inching_fwd=3,ch_inching_bwd=4, ...)

- (2.11.2-en_US) app_weld_set_weld_cond_analog(flag_dry_run=0, v_target=0, f_target=0, vel_target=0, vel_min=0, vel_max=0, weld_proc_param=[0.2,0.2,0.5,0.5,0.5,0.2,0.2,0.5,0.5])

- (2.11.2_temp-en_US) app_weld_weave_cond_trapezoidal(wv_offset=[0,0], wv_ang=0, wv_param=[0,1.5,0,-1.5,0.3,0.1,0.3,0.3,0.1,0.3])

- (2.11.2_temp-en_US) app_weld_weave_cond_zigzag(wv_offset=[0,0], wv_ang=0, wv_param=[3,0.6])

- (2.11.2_temp-en_US) app_weld_weave_cond_circular(wv_offset=[0,0], wv_ang=0, wv_param=[3,3,0.3,0.3])

- (2.11.2_temp-en_US) app_weld_weave_cond_sinusoidal(wv_offset=[0,0], wv_ang=0, wv_param=[3,0.6])

- (2.11.2-en_US) app_weld_adj_welding_cond_analog(flag_reset=0, v_target=None, f_target=None, vel_target=None, wv_offset=None, wv_width_ratio=None)

- (2.11.2-en_US) app_weld_get_welding_cond_analog()

- (2.11.2_temp-en_US) app_weld_weave_cond_trapezoidal(wv_offset=[0,0], wv_ang=0, wv_param=[0,1.5,0,-1.5,0.3,0.1,0.3,0.3,0.1,0.3])

- (2.11.2_temp-en_US) app_weld_weave_cond_zigzag(wv_offset=[0,0], wv_ang=0, wv_param=[3,0.6])

- (2.11.2_temp-en_US) app_weld_weave_cond_circular(wv_offset=[0,0], wv_ang=0, wv_param=[3,3,0.3,0.3])

- (2.11.2_temp-en_US) app_weld_weave_cond_sinusoidal(wv_offset=[0,0], wv_ang=0, wv_param=[3,0.6])