Welding Path Teaching that Takes Welding Pose into Account

In order to achieve uniform quality in welding work, a consistent pose must be maintained with regard to the target material. Teaching is easy when welding happens along a single straight line, but when welding corners or round materials, please refer to the following guide.

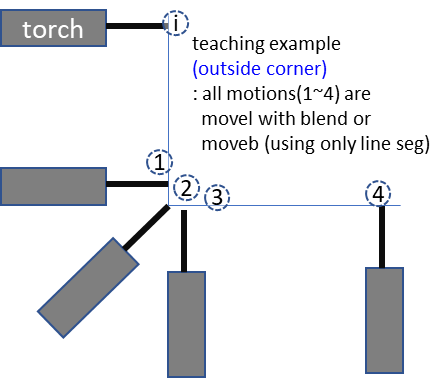

Teaching utilizing straight-line motion with regard to outside corners

As seen in the image below, a certain distance is kept from the corner and a stopover point is added to be used as a section in which the welding pose can be changed.

Teaching utilizing straight-line motion with regard to inside corners

Just as with teaching for outside corners, a certain distance is kept from the corner and a stopover point is added to be used as a section in which the welding pose can be changed.

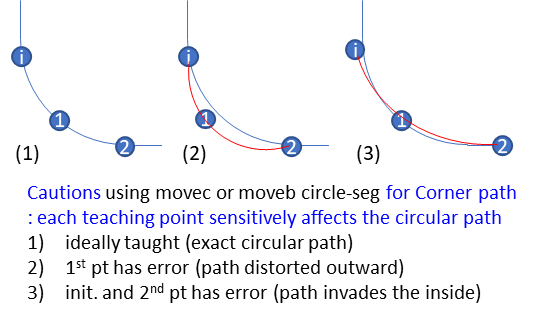

Things to watch out for when teaching corner areas using a circular arc motion

When teaching corners with a small radius using a circular motion (movec), even slight errors in the teaching points may result in an outwards or inwards distortion of the path on the material. In particular, when the TCP does not match the location of the end of the wire (when there is an error in the TCP value), the path error will be even greater. In the case of small corner areas, instead of utilizing a circle motion directly, it is recommended to use the line section of a line (movel) motion as in 1) and 2) or a blend motion (moveb) for the connection.