Securing the Robot

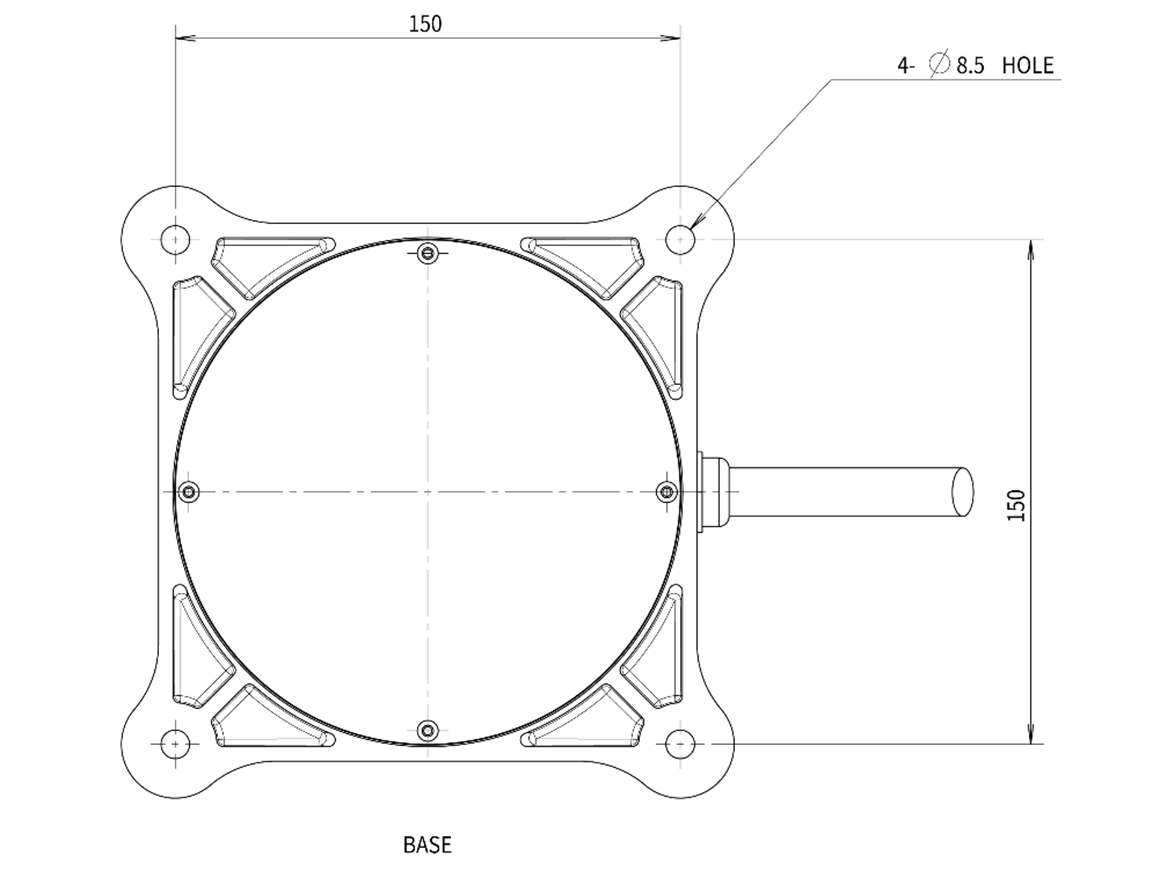

Use M8 bolts in the four 9.5 mm holes in the manipulator base to secure the robot.

- It is recommended to use a tightening torque of 20 Nm to tighten the bolts.

And use a washer(plain or spring) to prevent loosening of the tension caused by vibration.

- Use a Φ5 place marker pin to accurately install the manipulator in a fixed location.

manipulator base drawing, use four M8 bolts. Unit [mm]

Warning

- Tighten the bolts all the way to prevent loosening during manipulator operation.

- Install the manipulator base on a solid surface that can withstand the load generated during operation (10 times the maximum torque and five times the weight of the robot).

- The robot will interpret manipulator base vibration as a collision and engage the emergency stop. Therefore, for installation locations that automatically shift position, do not install the robot base in a location with high movement acceleration.

- Mount the manipulator arm in a specific location using appropriate methods. The mounting surface must be solid.

- The manipulator will be damaged if it comes in contact with water for an extended period of time. Do not operate the robot in conditions where it can get wet or under water.