Annex. P-Series Handling Guide

Caution

- Doosan Robotics does not assume responsibility for any damages that occurs during the use of lifting equipment.

- If the robot is transported by packaging it with packaging materials, store the robot in a dry location. If the robot is stored in a location with high humidity, condensation may occur, resulting in robot

- When relocating the robot, carefully consider the weight and have a suitable number of people hold the link and base of the robot.

- When relocating the controller, hold the handle on the side of the box.

- When transporting the robot or controller, make sure to maintain the proper posture. Failure to do so may result in back injury or other physical injuries.

- When transporting the robot using lifting equipment, make sure to observe all related national and regional regulations.

- Doosan Robotics does not assume responsibility for any damages or losses that occur during transportation, so make sure to transport the robot safely according to the user manual.

Quick Guide

Thank you for choosing this Doosan Robotics product.

This guide provides the minimum amount of information required for three handling methods for relocation and installation of the P-Series robot safely. Make sure to follow the instructions in this guide when handling the robot.

- If the robot needs to be relocated, be sure to use the packaging materials provided with the initial delivery. For this purpose, store the packaging materials and fillings in a dry, cool location.

- Industrial robot’s must be installed with careful consideration given to the inspection standards defined by the Regulations and Safety Inspection of the Occupational Safety and Health Standard Announcement (if the robot is subject to inspection).

- The robot can be transported using a crane, lift or hand lift, and when using a crane to lift the robot, be sure to comply with regulations of the area or country of jurisdiction.

- Utilize the packing posture for robot installation and relocation.

- Make sure whether all standard and additional (optional) components are included, and contact the sales agent if there are any problems.

- The packaging materials and bolts are designed specifically for the relocation of the robot. Do not use them for any purposes other than relocating the robot.

- When relocating the robot, do not apply force to the exterior of the robot. Failure to comply with these instructions may result in injuries.

- Remove the packaging materials and bolts after installation. Make sure to store the packaging materials and bolts in case the robot needs to be relocated.

- Before relocation, make sure that the bolts and packaging materials are secure.

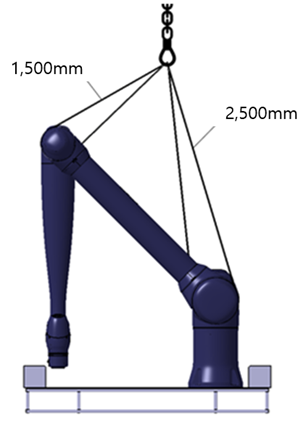

1. When a crane (hoist) is used- Use a spin-resistant cable capable of handling the weight of the robot.

Two types of wire ropes must be used, and the lengths of each wire rope must be 1,500 mm and 2,500 mm, respectively.

Item

Minimum Capacity

Crane

1,000 kg

Wire Rope (EA)

500 kg

1.1 Once the rope is secured to the robot frame,

- Please use the included rope after properly installing it between axes 1 and 2, and axis 3, depending on its length. (Refer to Figure below)

Before disassembling the robot fixing bolts, apply appropriate tension to the installed ropes to prevent the robot from falling over immediately after disassembling the fixing bolts.

Wire Rope Length

Device Location

2,500 mm

Between Axes 1 and 2

1,500 mm

Axis 3

Warning

For the safety of the user, both types of wire ropes included must be used, and failure to follow the instructions may result in unexpected safety accidents.

If you use a rope other than the included rope, be sure to follow the lengths provided.

When the robot is hoisted, the robot may tilt depending on environmental factors such as the wire rope installation status, robot posture, and optional attachment status, so be careful.

Do not walk under the robot body when lifting.

Note

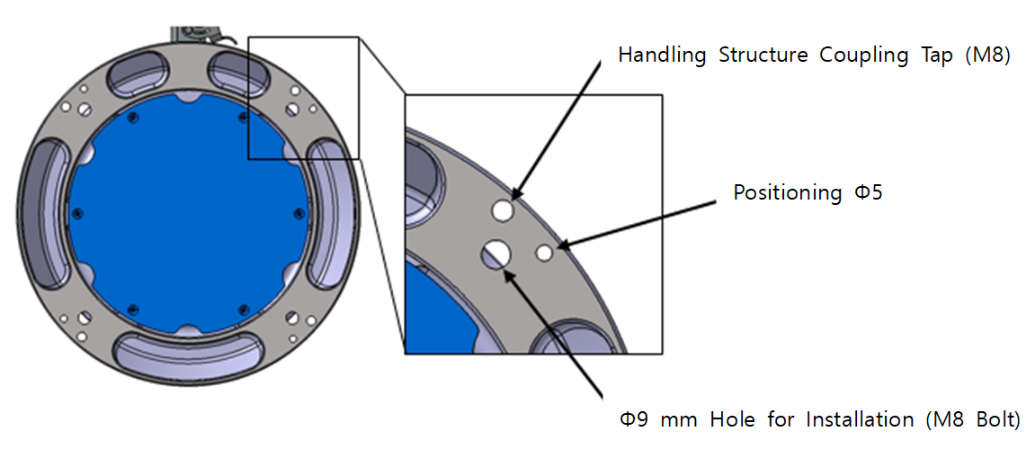

- For P-Series, four M8 Taps are applied to the base to facilitate handling.