Understand compliance/force control

OPTIONAL HARD 20 MIN

Force Control and Compliance Control are functions controlling robot force. These functions also control performing motion movement and force control if a motion command is added. Compliance control and force control have the following differences:

- Compliance control

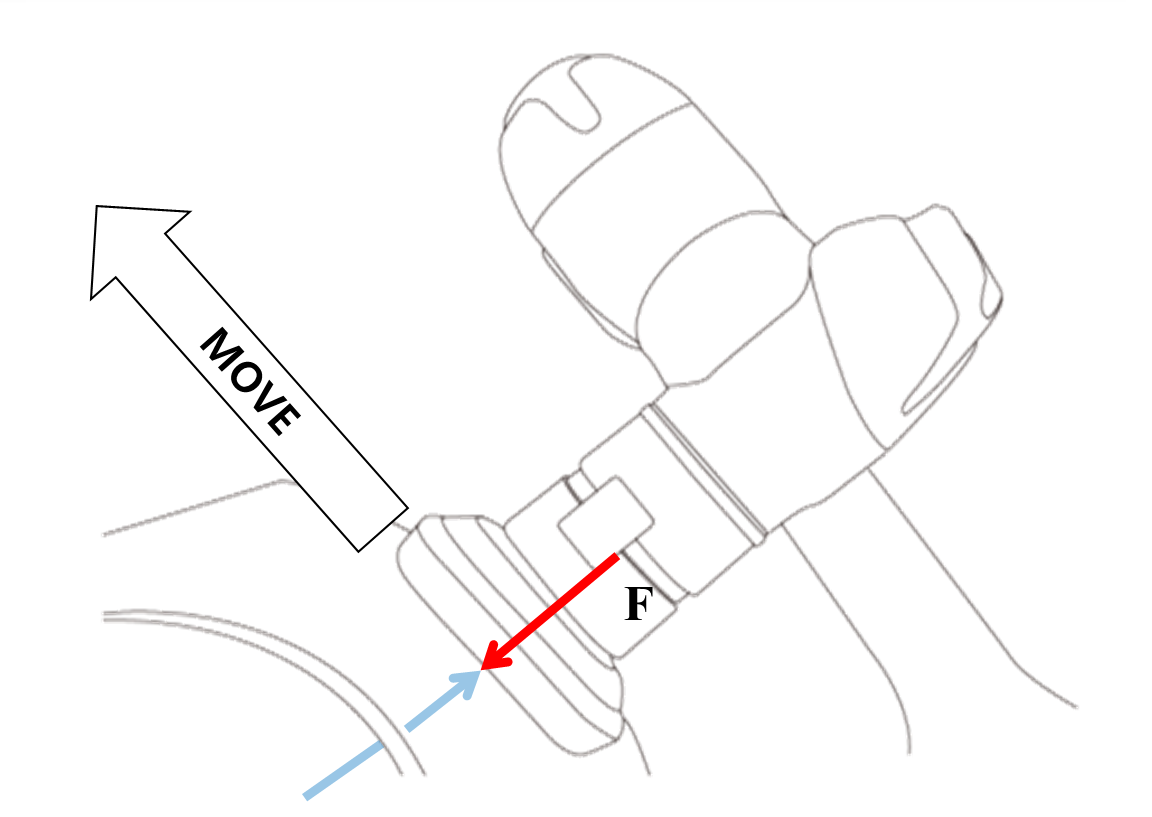

- The robot complies with external force at the robot end TCP during compliance control, and when the external force is removed, a force that returns the robot to its original position is created, causing the robot to move to the corresponding position.

- It can be used when linear motion is required on an uneven surface without damaging the robot and surface. It can be used to prevent unexpected collisions around the workpiece.

- Force control

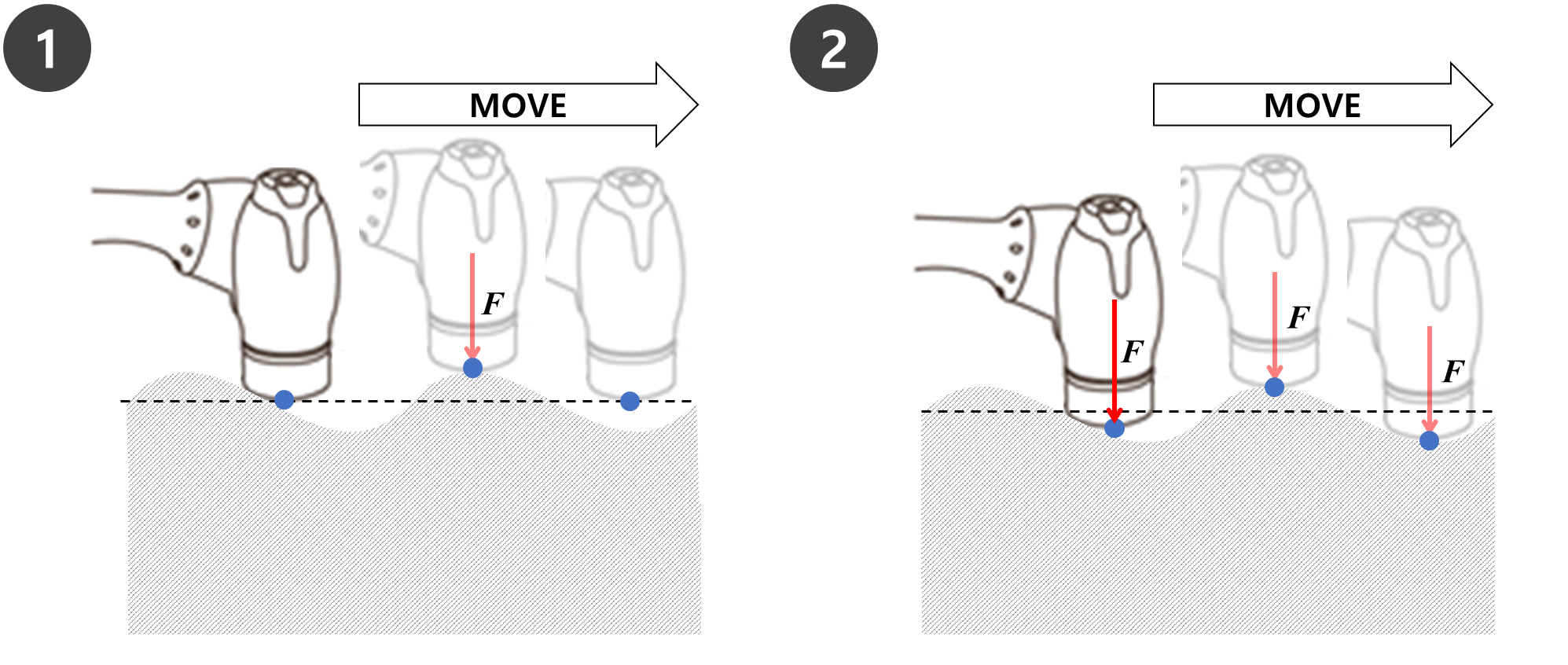

- During force control, force is generated at the robot end TCP. Acceleration is generated in the direction the force is generated, so the robot moves towards the motion direction as well as the force direction at the same time.

- When contact is made with an object, force will be applied on the object until the set force and the repelling force of the object form a balance.

- It can be used when equal force needs to be applied on a linear motion on an uneven surface. It can be used in tasks which require constant force while moving, such as polishing.

Note

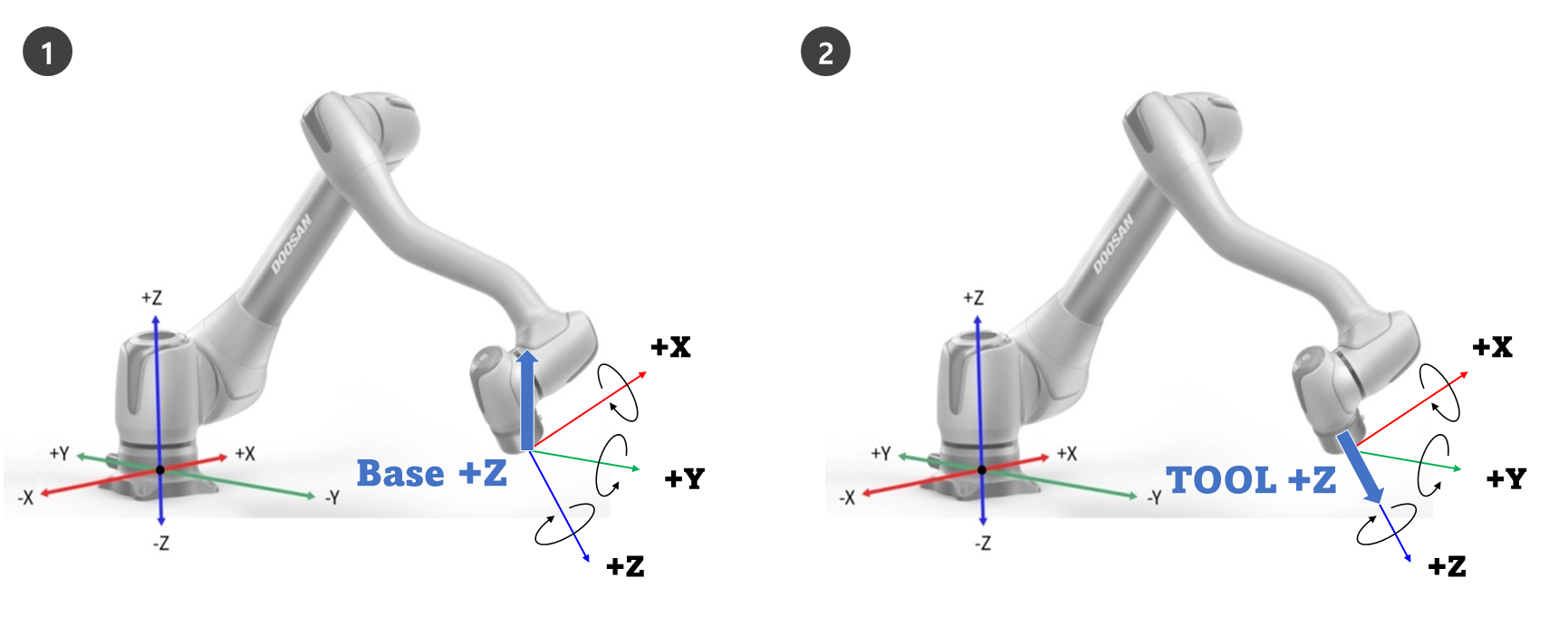

Compliance and Force Commands are executed based on the current coordinates. The default coordinate of a task is the Base coordinates, and the coordinates can be changed with the Set command.

- Fig. 1 is the operating direction when force/compliance control in the +Z direction is applied on the base coordinates.

- Fig. 2 is the operating direction when force/compliance control in the +Z direction is applied on the tool coordinates.

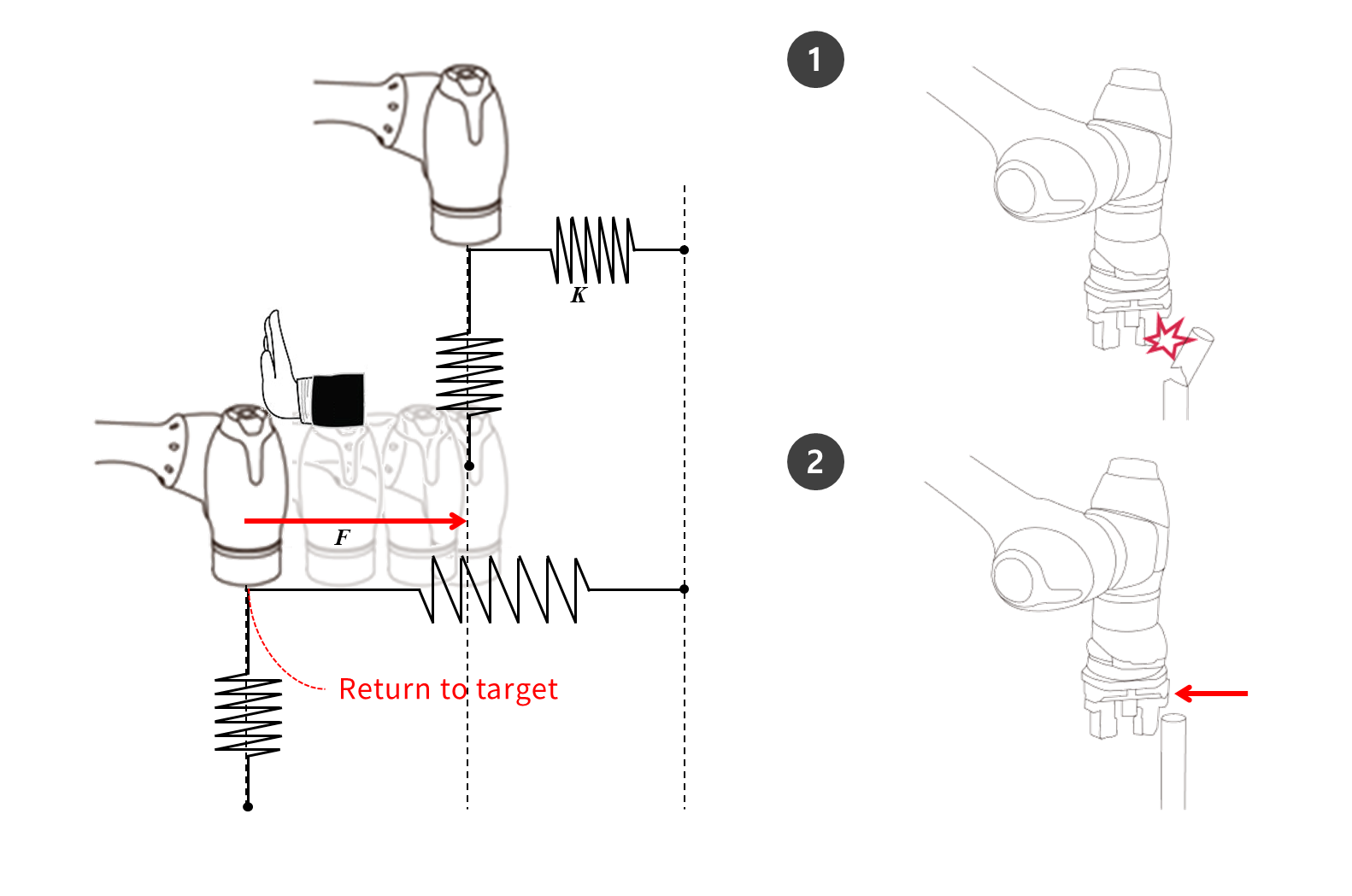

Compliance Control'

Compliance control is the function that complies to external force according to the set stiffness when force is applied on the robot end TCP. It balances forces at the target point, and it is a control method that generates repelling force if displacement occurs away from the balancing point. During compliance control, the robot end bounces like a spring.

- If collision is made when motion control is used alone, it is possible that the collided object may get damaged.

- Doosan Robotics robots stop safely when a collision occurs, but depending on the user setting, such as Safety Limits > Collision Sensitivity, the following situations may occur.

- If compliance control is set to on during motion control, the robot will move while complying to the collided object.

If F is external force, K is stiffness and X is distance, the following formulas are true.

- F = K * X

- K = F / X

- X = F / K

Based on the above formulas, if the stiffness of compliance control is set to 1000N/m and if the robot moves 1 mm, the external force generated is 1N.

- F=1000 N/m*0.001 m=1 N (0.001 m=1 mm)

Note

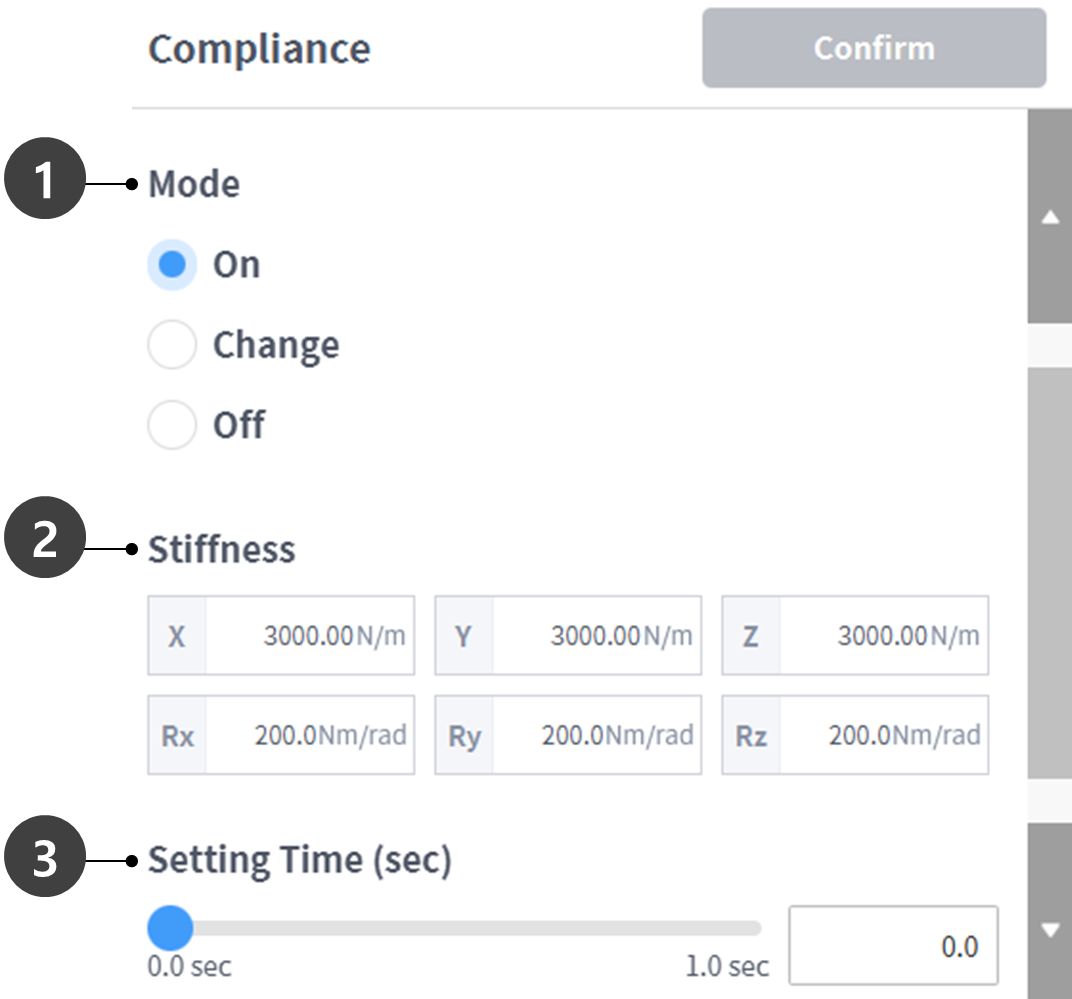

On the Property of Compliance Command, the following values can be set:

- Mode

- On: Enables compliance control

- Change: If compliance mode is set to On, it changes to stiffness

- Off: Disables compliance control

- Stiffness Range

- M/H Series : Translation(0~20000N/m), Rotation(0~1000Nm/rad)

- A Series : Translation(0~10000N/m), Rotation(0~300Nm/rad)

- Lower stiffness values will respond to external force more gently and will require more time to return to the target point

- Setting Time

- It is the time required for the current stiffness value to reach the set stiffness value (0-1s)

Caution

- Tool weight and TCP (Tool Center Point) must be accurately set. Inaccurate tool weight can cause the robot to detect the tool weight as external force, and setting the Compliance Command On will generate position error.

- Tension of the dress pack may generate external torque on the robot. Therefore, take caution when installing the dress pack.

- Compliance cannot be turned on or off while async motion or blending motion is being executed.

- During Compliance Command on, only linear motion is allowed. Joint motions, such as MoveJ and MoveSJ, are not allowed.

- During Compliance Command On, Tool Weight or TCP cannot be changed.

- During Compliance Command on, it is possible to not accurately reach the target point due to compliance of the torque generated during motion execution. Therefore, it is recommended to turn on compliance control near the target point. Or, it is possible to minimize position error by setting a large stiffness value.

Force Control

Force Control is a function that applies force in the force control direction until the set force and repelling force form a balance

- It moves the robot in the set force direction, and if contact with an object is made, it maintains the entered force (N)

- It is capable of motion control in a direction different from the force direction while applying a constant force

- The minimum setting is +/- 10N, and it can be fine-tuned with a resolution of 0.2N

- Force Control is unavailable in singularity zone

- In general, Compliance Control is used in conjunction with force control so that force control complies to external force

Note

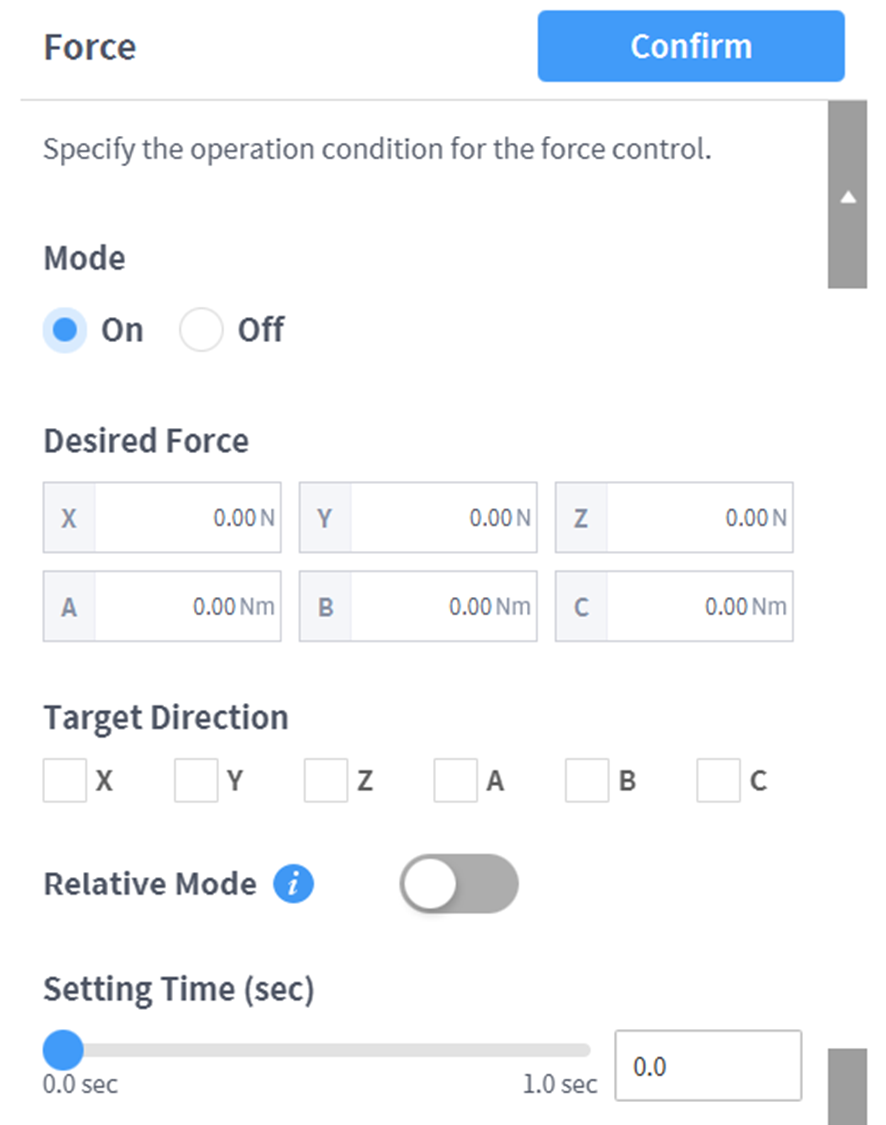

From the property of Force Command, the following values can be set.

- Mode

- On: Enables Force Control

- Off: Disables Force Control

- Desired Force Range

- X, Y, Z: 10 - (each robot’s maximum) N

- A, B, C: 5 - (each robot’s maximum) Nm

- For more information about maximum force, refer to Upper/Lower Threshold Range and Default Value of Safety Parameters.

- Target Direction

- It moves to the selected target value of each direction.

- Multiple selections can be made.

- Force control can only be executed with direction setting after force setting.

- If one of the multiple selected directions reaches the target force, it will continue to move until the target value is reached for the other direction.

- Relative Mode

- If this mode is enabled, it calibrates the external force applied on the robot to 0 to improve the force control accuracy.

- When relative mode is disabled, the actual force applying on the target is equal to the sum of the set force and external force.

- When relative mode is enabled, the actual force applying on the target is equal to the set force.

- During force control, deviation can occur depending on the pose or external force.

- During force control, it is possible not to reach the exact target point. Therefore, it is recommended to enable force control near the target point.

- If this mode is enabled, it calibrates the external force applied on the robot to 0 to improve the force control accuracy.

- Setting Time

- It is the time required for the current force value to reach the set force value (0-1s)