(2.11.2-en_US) set_conveyor_ex(name=””, conv_type=0, encoder_channel=1, triggering_mute_time=0.0, count_per_dist=5000, conv_coord=posx(0,0,0,0,0,0), ref=DR_BASE, conv_speed=100.0, speed_filter_size=500, min_dist=0.0, max_dist=1000.0, watch_window=

Features

Configures the conveyor and obtains Conveyor ID to allow the Conveyor Tracking Application to start. After the command is executed, it monitors workpieces triggered in the configured conveyor until the program ends. It can be used when you need to set parameters manually if is unavailable to configure conveyor information through UI.

1) Added default value for all arguments compared to versions prior to M2.4.0

2) Added ‘ref’ argument compared to versions prior to M2.4.0 (world coordinates available)

3) Removed ‘obj_offset_coord’ argument compared to versions prior to M2.4.0, The ‘obj_offset_coord’ argument is changed to input only in get_conveyor_obj() function.

Parameter

| Parameter Name | Data Type | Default Value | Description |

|---|---|---|---|

name | string | “” | Conveyor name |

conv_type | int | 0 | Conveyor type(0: Linear, 1: Circular) |

encoder_channel | int | 1 | External encoder channel (1, 2) |

triggering_mute_time | float | 0.0 | It is the time (s) triggering (encoder reset, start workpiece tracking) is not performed when a triggering signal is received immediately after triggering. |

count_per_dist | int | 5000 | Encoder count converted value per length (Linear: count/m, Circular: count/rad) |

conv_coord | posx | posx(0,0,0,0,0,0) | Fixed conveyor coordinates (based on Base/World coordinates, mm, ˚) |

list (float[6]) | |||

ref | int | DR_BASE | Reference coordinates of conveyor coordinates (DR_BASE: Base, DR_WORLD: World) |

conv_speed | float | 100.0 | Conveyor nominal velocity (Linear: mm/s, Circular: ˚/s) |

speed_filter_size | int | 500 | Moving Average Filter Size during conveyor velocity filtering |

min_dist | float | 0.0 | Minimum conveyor work length (based on Triggering Switch, Linear: mm, Circular: ˚) |

max_dist | float | 1000.0 | Maximum conveyor work length (based on Triggering Switch, Linear: mm, Circular: ˚) |

watch_window | float | 100.0 | Conveyor work standby monitoring length (based on minimum work length, Linear: mm, Circular: ˚) |

out_tracking_dist | float | 10.0 | Conveyor tracking release buffer section length (based on maximum work length, Linear: mm, Circular: ˚) |

Note

- Currently conv_type argument does not support Circular Conveyors!

- All workpieces that pass the Triggering Switch are monitored until they reach max_dist after set_conveyor() or set_conveyor_ex() function execution and before the program ends.

- However, if triggering_mute_time is configured, and if the Triggering Switch activates during the corresponding time after the previous workpiece is detected, it is not included on the monitoring list. It is used when noise is present in the Triggering Switch or when the workpiece needs to be removed for a certain amount of time.

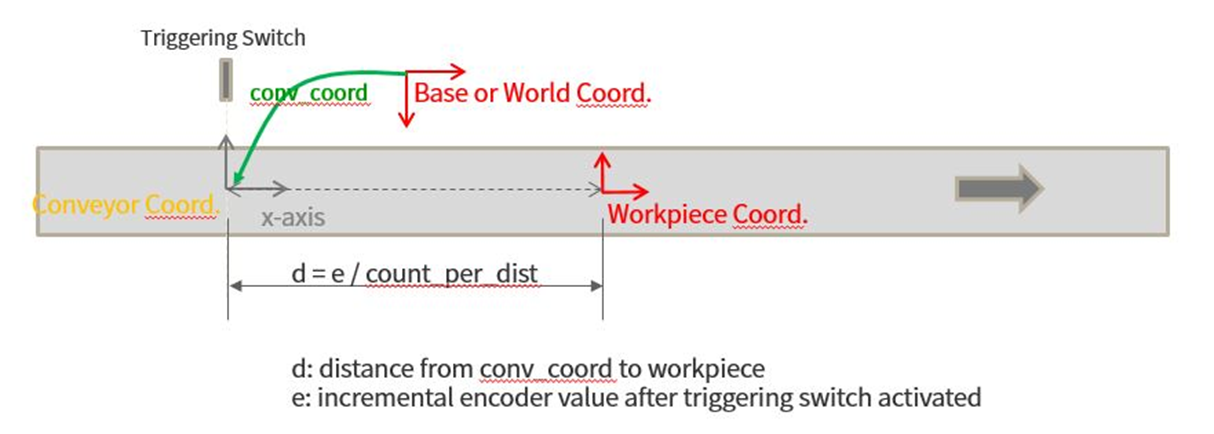

- conv_coord is a coordinate system fixed to the conveyor relative to the base or world coordinate system. Here, the x-axis of conv_coord represents the direction the conveyor flows. From the moment the conveyor workpiece activates the triggering switch, the increased encoder value can be converted to the length of the workpiece travel by using the count_per_dist argument, and extending this length in the x-axis direction of the conv_coord will position the workpiece relative to the reference coordinate system.

[Conveyor/Item Coordinate]

- conv_speed is the moving speed of the conveyor. It is used to give Info only if the conveyor speed sensed by the encoder exceeds 200% of this speed. Therefore, if the measurement is not possible through the TP UI, enter the approximate value.

- Speed_filter_size is the size of the moving-average filter used to estimate the conveyor speed from the encoder. The larger the size, the more the noise can be canceled, but the tracking accuracy may deteriorate during acceleration and deceleration.

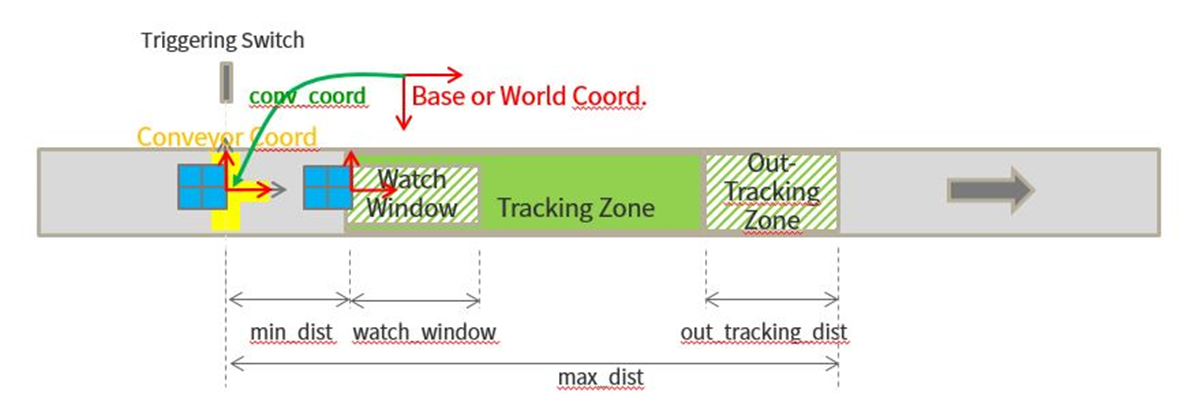

- The area on top of the conveyor is categorized into Watch Window, Tracking Zone and Out-Tracking Zone.

- Watch Window is the area that determines whether workpieces within the area are available for the job when obtaining workpiece coordinates for tracking. When the get_conveyor_obj() function is loaded, if a workpiece is not present within this area, the function is not returned, and if a workpiece is present within this area, it returns workpiece coordinates according to get_conveyor_obj() function options (FIFO, LIFO).

- The Tracking Zone is the area that performs Conveyor Tracking.

- The Out-Tracking Zone is the area where the robot automatically ends tracking after it determines that the robot has exited the work space of the robot or the work space specified by the user during continuous tracking.

- These three areas are defined with the four lengths (min_dist, max_dist, watch_window, out_tracking_dist) as shown below.

[Conveyor Area and Length]

Return

| Value | Description |

|---|---|

Conveyor ID | Returns Conveyor ID if conveyor setting is successful |

None | Conveyor setting failure |

Exception

| Exception | Description |

|---|---|

DR_Error (DR_ERROR_TYPE) | Parameter data error occurred |

DR_Error (DR_ERROR_VALUE) | Parameter value is invalid |

DR_Error (DR_ERROR_RUNTIME) | C Extension module error occurred |

DR_Error (DR_ERROR_STOP) | Program terminated forcefully |

Example

CONV1 = set_conveyor_ex(name=‘conveyor_1’,

conv_type=0, # linear

encoder_channel=1, triggering_mute_time=0.0,

count_per_dist=5000, # 5000 count/mm)

conv_coord=posx(500, 100, 500, 0, -90, 0), ref=DR_BASE,

conv_speed=100.0, # conveyor speed: 100 mm/s,

speed_filter_size=500, # moving avg. filter size: 500 ms

min_dist=100, max_dist=1000, watch_window=200, out_tracking_dist=10)

Related commands

- (2.11.2-en_US) get_conveyor_obj(conv_id, timeout=None, container_type=DR_FIFO, obj_offset_coord=None)

- (2.11.2_temp-en_US) tracking_conveyor(conv_id, time=0.3)

- (2.11.2-en_US) untracking_conveyor(conv_id, time=0.3)